Lately, you may have noticed an alarming trend of skincare and beauty brands being called out for mold growing in their products. I recently listened to an episode of Gloss Angeles where hosts Kirbie and Sara referenced a Beauty Independent article titled: “Is the Beauty Industry Suffering From a Product Quality Crisis?”

This really got me thinking—as Head of New Product Development at my company, it’s always been my responsibility to ensure the safety and quality of our products. I’m no stranger to problems with microbial growth or instability showing up during product testing, this is par for the course. It’s normal for those issues to come up during the R&D stage and when they do, no biggie! We can solve for that. But when a product is already out on the market and starts to exhibit these types of issues, it’s a whole other story.

In light of this, I thought I’d dive into how mold ends up in skincare products, how it can be prevented, and why we might be seeing this issue more often than we used to.

What Causes Mold To Grow In Skincare Products?

Grab any skincare product off your vanity and look at the ingredient list—chances are, water is a top ingredient. Water is the primary carrier used in all skincare formulas (with the exception of a few waterless formats). For the most part, you’d be hard-pressed to find a skincare product that doesn’t contain H2O.

What does this have to do with mold, you ask? Microorganisms such as mold, yeast, and bacteria rely on water to live as much as we do. Essentially, the presence of water in a skincare product is a pretty big indicator that it could be at risk for microbial contamination.

Contamination During Manufacturing

The FDA requires all personal care products to be safe and not harmful to customers in any way. While this requirement may sound vague, a majority of brands and manufacturers follow a set of well-established guidelines called Good Manufacturing Practices in order to make sure their products meet FDA safety criteria.

Most labs know that when they’re making products, they have to account for the presence of bacteria, yeast, or mold on the manufacturing equipment. Labs are not completely sterile environments, and manufacturing is a very wet process; even the aforementioned waterless skincare requires lots of water to be made! It’s just something you can’t get around. This is why it’s incredibly important for manufacturers to follow proper safety and cleaning procedures to prevent contamination.

The reality is that trace amounts of yeast, bacteria, and mold can be found in almost all skincare and beauty products. I know this sounds gross, but it’s actually not something you need to worry about. The key is keeping these microorganisms at harmless levels and preventing them from proliferating—which is where preservatives come in.

Contamination At Home

Skincare products continue to be exposed to moisture even after leaving the lab. This could be from your shower, your bathrooms sink, your hands, or even just humidity in the air. This is why it’s so important for products to be formulated with a proper preservation system. You can minimize the risk of contamination by washing your hands before dipping them into jars, keeping products in a dry environment, and keeping them out of excessive heat or direct sunlight.

Ultimately though, it’s up to the brand and manufacturer to make sure that your products are thoroughly tested, preserved, and stabilized. As long as a product is manufactured in a clean environment following proper guidelines, preservatives keep harmful microorganisms in check and at levels that are not dangerous to humans. This is why clean beauty products that forego traditional preservatives are at higher risk for growing mold and other contaminants.

Why Are We Hearing About Mold in Beauty Products More Often?

It seems too often lately that we hear about companies recalling a skincare or beauty product due to possible mold contamination. Why is this? It’s hard to say exactly, but the way I see it, there are two likely culprits.

One is, as I mentioned, the clean beauty movement. This movement has villainized certain ingredients (like preservatives), which has created unnecessary fear among consumers. Because consumer preference is such a strong, driving force, we’ve seen more widespread use of less studied, less efficacious preservative methods being selected in lieu of traditional preservatives.

Another reason we may be seeing mold in products more often is the increasing pressure on companies to keep up with trends. Thanks to Instagram and TikTok, trends in skincare and beauty come and go faster than ever before. In some cases, brands are racing to keep up with these trends in order to capitalize on them before it’s too late. This can sometimes lead to the cutting of corners in regard to product safety testing.

How Can You Tell If Mold Is Present In Your Skincare?

The good news is, it’s not hard to tell when your products are growing mold.

Mold typically has a very distinct look and has either dark coloring or a white, fuzzy appearance. More often than not, it will also emit a smell. In fact, a shift in smell, color, or consistency will often let you know a product is on its way out long before you actually start to see mold. It’s definitely worth keeping an eye out for any changes and noting the expiration date of your skincare products. (Here’s how to determine the expiration date of a product.)

What Are The Dangers Of Mold In Skincare Products?

If you have a healthy immune system and strong skin barrier, you likely won’t experience any side effects stronger than redness, irritation, or mild burning on the skin. You may not even know where these side effects are originating from if your product isn’t exhibiting signs of contamination.

However, those who are immunocompromised should be careful, especially if applying products over broken skin. It’s also important to exercise caution when applying eye products, as contaminated products can serve as a breeding ground for eye infections. So again, if your product doesn’t look or smell right, or if it’s simply past its expiration, it’s always best to throw it out.

The Growing Importance Of Product Testing Procedures

As the head of New Product Development within my own company, I’m very happy there is a growing awareness of this issue within the beauty community. A flood of recalls and manufacturing errors lately have left people wondering—and rightly so.

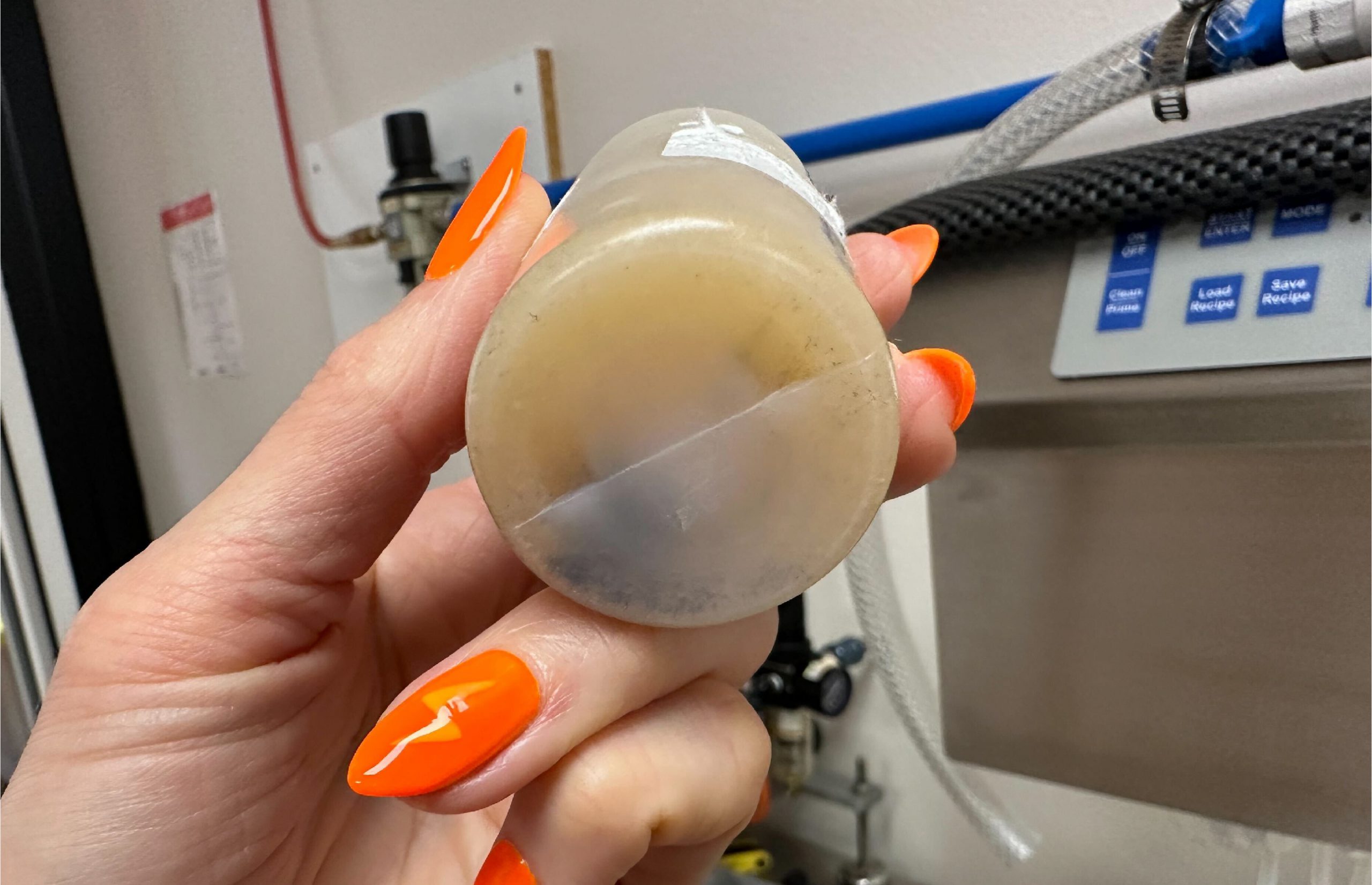

At a company, quality is everyone’s responsibility, but it first starts with leadership. There are lots of moving parts and pieces involved in bringing a product to market, and it’s possible for things to fall through the cracks. Researching and developing new products is not easy and it takes some time. Take my newest creation, Better Than Balm, as an example. It took over two years to perfect this formulation, but every trial and error led me to the safe, efficacious, award-winning product we have today. As frustrating as the formulation and testing process can be, it’s important not to rush it.

In my opinion, it’s also extremely important to establish good communication with your labs so you can make sure they’re putting your products through all the necessary testing parameters. This includes Preservative Efficacy Testing (PET), which is part of the Good Manufacturing Practices I mentioned earlier. This is the testing that ensures your products can withstand microbial contamination, including mold.

I want to add that a majority of brands are responsible when it comes to these manufacturing processes. The last thing any brand wants is to put its customers and reputation at risk. Mold contamination is still fairly rare, but it is possible. As a consumer, it’s good to be armed with the necessary knowledge so you can spot this issue should it arise.

Celebrity Esthetician & Skincare Expert

As an esthetician trained in cosmetic chemistry, Renée Rouleau has spent 30 years researching skin, educating her audience, and building an award-winning line of products. Her hands-on experience as an esthetician and trusted skin care expert has created a real-world solution — products that are formulated for nine different types of skin so your face will get exactly what it needs to look and feel its best. Trusted by celebrities, editors, bloggers, and skincare obsessives around the globe, her vast real-world knowledge and constant research are why Marie Claire calls her “the most passionate skin practitioner we know.”